1*7 1*19 7*7 7*19 Steel cable rope steel wire cable Galvanized steel wire rope

Product Description

1*7 1*19 7*7 7*19

Galvanized steel wire rope is constructed of galvanized wires which are dipped in the tank containing molten zinc to form a thick layer of zinc coating before the wire is drawing through dies. Then these galvanized wires are drawn to reduce diameter and increase tensile strength. At the same time, zinc coating bonding to steel wires is compressed to form a more excellent layer to protect the steel form corroding.

Galvanized steel wire rope is divided into two categories: cold galvanized steel wire rope and hot-dip galvanized steel wire rope. Hot-dip galvanizing and cold-dip galvanizing have this essential difference in the process. Hot-dip galvanizing relies on physical thermal diffusion to form a coating. First, iron-zinc compounds are formed, and then a pure zinc layer is formed on the surface of the iron-zinc compounds. The essential difference between hot-dip galvanized steel wire rope and cold-dip galvanized steel wire rope is that the zinc layer of hot-dip galvanized steel has better corrosion resistance due to the zinc-iron alloy layer than cold galvanized steel. The surface condition of the hot-dip galvanized steel wire rope is blackened because of the hot-dip galvanized iron alloy. The electroplated surface has no chemical reaction, so it is still the original color of zinc, which looks brighter. In general, the zinc layer of hot-dip galvanizing is thicker, and the corrosion resistance is better. The zinc layer of electro-galvanized zinc is thinner and has poorer corrosion resistance. (Unless the zinc layer of cold galvanizing also reaches the level of thick zinc layer)

Galvanized steel wire rope can be used in high-level construction, blockade, fence, clothesline, vehicle and ship binding, towing, strapping and other fields; used in shipping, offshore oil exploration, aircraft manipulation, marine fishing, trawling, fixed net, roll net and other fisheries .

Production Process

Specification

|

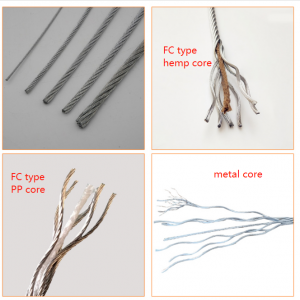

Structure |

1*7,7*7(6*7+FC, 6*7+IWS,6*7+IWRC), 1*19,7*19(6*19+FC,6*19+IWS,6*19+IWRC),19*7, etc. |

|

Diameter |

0.3mm --12mm |

|

Material |

Carbon steel 45#,55#,60#,70# |

|

Standard |

DIN, EN, ABS, BS, JIS, LR etc. |

|

T/S |

1570-1960Mpa |

|

Tolerance |

±3% |

|

Diameter (mm) |

Approx weight (kg/100m) |

Min. Breaking Load (Kn) |

|

|

1*7 |

0.30 |

0.05 |

0.098 |

|

0.40 |

0.08 |

0.176 |

|

|

0.50 |

0.13 |

0.284 |

|

|

0.60 |

0.18 |

0.402 |

|

|

0.80 |

0.32 |

0.705 |

|

|

1.00 |

0.50 |

1.078 |

|

|

1.20 |

0.72 |

1.520 |

|

|

1.40 |

0.98 |

2.060 |

|

|

1.50 |

1.13 |

2.350 |

|

|

1.60 |

1.28 |

2.650 |

|

|

1.80 |

1.62 |

3.330 |

|

|

2.00 |

2.0 |

4.120 |

|

|

1*19 |

0.80 |

0.32 |

0.686 |

|

1.00 |

0.50 |

1.030 |

|

|

1.20 |

0.72 |

1.470 |

|

|

1.50 |

1.12 |

2.450 |

|

|

1.60 |

1.27 |

2.740 |

|

|

1.80 |

1.61 |

3.330 |

|

|

2.00 |

2.00 |

4.170 |

|

|

2.50 |

3.10 |

6.520 |

|

|

3.00 |

4.50 |

8.330 |

|

|

3.50 |

6.13 |

10.80 |

|

|

4.00 |

8.00 |

13.70 |

|

|

Diameter |

Approx weight |

Min. Breaking Load |

||

|

(mm) |

(kg/100m) |

1570Kn/mm2 |

1770Kn/mm2 |

1960Kn/mm2 |

|

|

7*7 |

0.36 |

0.05 |

0.079 |

0.089 |

0.097 |

|

0.45 |

0.08 |

0.124 |

0.140 |

0.151 |

|

|

0.50 |

0.10 |

0.153 |

0.172 |

0.186 |

|

|

0.60 |

0.15 |

0.220 |

0.248 |

0.268 |

|

|

0.80 |

0.26 |

0.390 |

0.440 |

0.477 |

|

|

0.90 |

0.33 |

0.495 |

0.560 |

0.600 |

|

|

1.00 |

0.41 |

0.610 |

0.690 |

0.760 |

|

|

1.20 |

0.58 |

0.880 |

0.990 |

1.100 |

|

|

1.50 |

0.91 |

1.370 |

1.550 |

1.710 |

|

|

1.80 |

1.32 |

1.970 |

2.230 |

2.460 |

|

|

2.00 |

1.62 |

2.440 |

2.540 |

2.810 |

|

|

2.20 |

1.97 |

2.960 |

3.300 |

3.510 |

|

|

2.50 |

2.54 |

3.810 |

4.290 |

4.750 |

|

|

3.00 |

3.65 |

5.480 |

5.720 |

6.330 |

|

|

4.00 |

6.50 |

9.750 |

10.200 |

11.300 |

|

|

5.00 |

10.15 |

15.230 |

15.900 |

17.600 |

|

|

6.00 |

14.62 |

21.900 |

22.900 |

-- |

|

|

8.00 |

25.98 |

39.000 |

40.700 |

-- |

|

|

10.00 |

40.60 |

60.900 |

63.500 |

-- |

|

|

12.00 |

58.46 |

87.700 |

91.500 |

-- |

|

|

7*19 |

1.50 |

0.92 |

1.26 |

1.43 |

1.58 |

|

1.80 |

1.32 |

1.82 |

2.05 |

2.27 |

|

|

2.00 |

1.63 |

2.27 |

2.56 |

2.81 |

|

|

2.20 |

1.98 |

2.72 |

3.06 |

3.39 |

|

|

2.50 |

2.55 |

3.55 |

4.00 |

4.43 |

|

|

3.00 |

3.68 |

5.12 |

5.77 |

6.39 |

|

|

4.00 |

6.53 |

9.09 |

10.25 |

11.35 |

|

|

5.00 |

10.21 |

14.21 |

16.02 |

17.74 |

|

|

6.00 |

14.70 |

20.50 |

23.10 |

25.50 |

|

|

8.00 |

26.14 |

36.40 |

41.00 |

45.40 |

|

|

10.00 |

40.84 |

56.80 |

64.10 |

71.00 |

|

|

12.00 |

58.81 |

81.80 |

92.30 |

-- |

|

Related PRODUCTS

-

E-mail

-

Phone

-

Whatsapp

whatsapp

-

Wechat

Wechat

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu